Failing to properly maintain building assets could cost a lot. Building deterioration, building occupant dissatisfaction and falling rental rates are obvious effects of bad maintenance. Sudden equipment downtime can also have a significant impact on service delivery and lost production time, according to a survey of 450 IT and field service decision-makers.

The role of facilities managers is to avoid such outcomes. In order to do so, they undertake a variety of activities.

Managing Assets

The heart of maintenance management is asset management. Asset management has three stages:

- Procurement: This stage involves finding appropriate items, surveying the market, calling for quotations, planning for implementation, buying, installation and deployment.

- Operational Maintenance: This involves servicing the equipment to ensure its normal operation. The equipment should operate for the longest possible useful life and maintenance costs should be kept reasonable.

- Disposal: A decision would need to be taken as to the appropriate time for asset upgrade or disposal. Facilities Managers play a key role in making these decisions and are also actively involved in the disposal, replacement or upgrade process.

Managing Staff

Maintaining a building takes a team, which may include technicians, cleaning, security, landscapers and pest control. The day-to-day role of facility manager typically involves coordinating the work of these team members.

Typical workforce management tasks include:

- Employing and appointing new maintenance workers

- Induction of new workers

- Proper training and qualification of workers

- Establishing required procedures and necessary safety guidelines

- Motivating and monitoring workers

- Assigning tasks

- Developing preventive maintenance checklists

- Planning preventive maintenance schedules

- Ensuring proper completion of tasks

Managing Vendors

A facility manager interacts with many equipment and service vendors. For example, cleaning or security services may be provided by other companies. Building facade cleaning, specialist equipment like lifts or original equipment maintenance personnel are usually provided by third party vendors. Installed building management systems, fire systems, access control and software vendors are typically not provided in-house.

Activities involved in managing maintenance vendors include:

- Hiring contractors that are suitable for specialized maintenance

- Negotiating contracts

- Ensuring policy compliance and monitoring performance

- Discussing changes and problems that might arise in the future

- Tracking costs for each contractor

Managing Expenses

Facilities managers typically work within a specified maintenance budget, which includes all headcount related expenses, contractor fees and fees for consumables and spare parts. Facilities managers may also be involved in capital expenditure decisions like asset replacement, asset enhancement decisions or implementation of new systems. The challenge for the facility manager is to ensure the achievement of the outcomes specified above within the specified budget amount.

Expense management tasks may include

- Recording all expenditures and gathering expenditure data

- Seeking approvals for certain expenditures

- Proposing necessary additional expenditures and justifying these expenditures

- Projecting and annual budgeting, including asset replacement recommendations

- Finding areas for cost-saving and productivity improvements

Customer Service

Ultimately, the facility manager works together with the building manager to ensure that building occupants can live, work and play in a conducive environment. Therefore, the facility managers are in daily communication with building occupants to address their fault reports and service requests. Integrated facilities managers may even be engaged for soft service roles that may not be directly equipment maintenance related, including reception, mail room, catering, car park management, pantry management and event management.

Specifically, the scope of activities includes:

- Responding to fault reports and service requests

- Ensuring requests are addressed within a specified time

- Communicating with building occupants

- Gathering feedback and satisfaction level data

- Recommending ways to improve building occupant satisfaction levels

Maintenance Approaches

Facilities managers adopt several different approaches to equipment management. A typical facilities management operation typically contains of a mix of the following approaches:

- Reactive maintenance (RM): Reactive maintenance is the process of allowing channels of fault reporting, gathering these fault reports as tickets to be resolved, and ensuring resolution of these fault reports. This is a basic facilities management process and is undertaken in almost all facilities management operations.

- Preventive maintenance (PM): Preventive maintenance involves setting a regular maintenance schedule and performing checks even if there has been no reported equipment issues. Technicians, armed with checklists, will be scheduled for these checks.

- Condition-based maintenance (CBM) is an approach utilizing sensors or tests performed to determine when maintenance is necessary.

- Utilization-based maintenance is a regime where maintenance checks are performed when a certain utilization metric has been reached.

- Predictive maintenance (PdM) uses machine learning to predict when a piece of equipment is likely to have an issue.

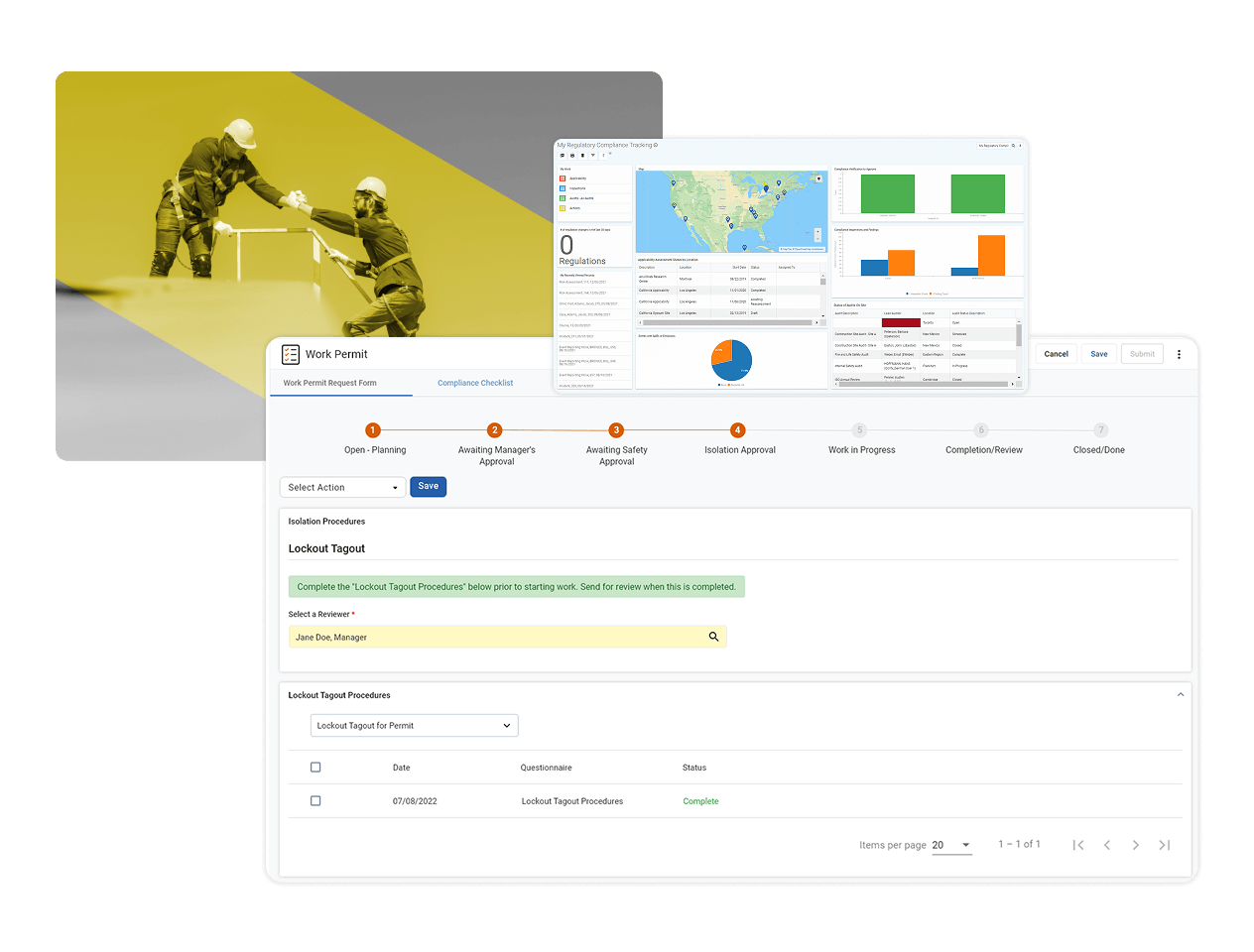

Maintenance Management Software

Given the complexity of facilities management, utilizing software to digitize and automate maintenance management processes can be of great help.

Whilst past facilities management operations may have tried to cope with manual and paper based systems, relying on such manual processes today is inefficient, tedious, error prone, environmentally unfriendly and leads to bad customer service and decision making.

Modern facilities management systems can provide many benefits, including:

- Managing all fault reports and service requests: Building occupants can report faults and make service requests convenient through a single channel. The software tickets and tracks completion of all these requests.

- Automated workflows: Fault reports and service request tickets can be automatically assigned to the appropriate responder. Preventive maintenance checklists can be automatically assigned. Other workflows, such as expenditure approvals can also be automated.

- Centralized asset database: The software acts as the single source of truth for all parties. Key information such as asset details, maintenance history, checklist completion and request completion are held in a single repository and easily searched and accessed.

- Photo and Video Evidence: Photos and videos can be attached to fault reports, service requests and checklists. Such evidence is useful for management oversight, audits and future decision making.

- Statistics, KPIs and Data Analytics: Facilities managers need to make reports to building management, including adherence to specified KPI thresholds. Data analytics is key for data-driven decision making.

- Procurement Transparency and Expenditure Tracking: Procurement activities can be made through the facilities management system, increasing procurement transparency. All maintenance expenditures can be tracked in a single system.

Communication with Building Occupants: The best facilities management software also supports engagement with Building occupants, including sending broadcast messages, surveys, gathering feedback and satisfaction levels.