Modern facilities and asset-intensive enterprises face rising pressure to keep equipment running longer, reduce operating costs, and improve capital efficiency. With maintenance accounting for up to 40% of total operational spend in some industries, organizations are actively searching for technologies that deliver real EAM cost savings and stronger asset management ROI.

Enterprise Asset Management (EAM) software has emerged as one of the most powerful solutions for controlling maintenance expenses, improving asset performance, and optimizing lifecycle decisions. Platforms like FacilityBot extend these capabilities with automation, preventive maintenance scheduling, mobile workflows, and analytics—making maintenance more predictable and cost-efficient.

In this article, we explore how EAM software reduces costs, improves returns, and supports long-term asset sustainability.

What Is EAM Software?

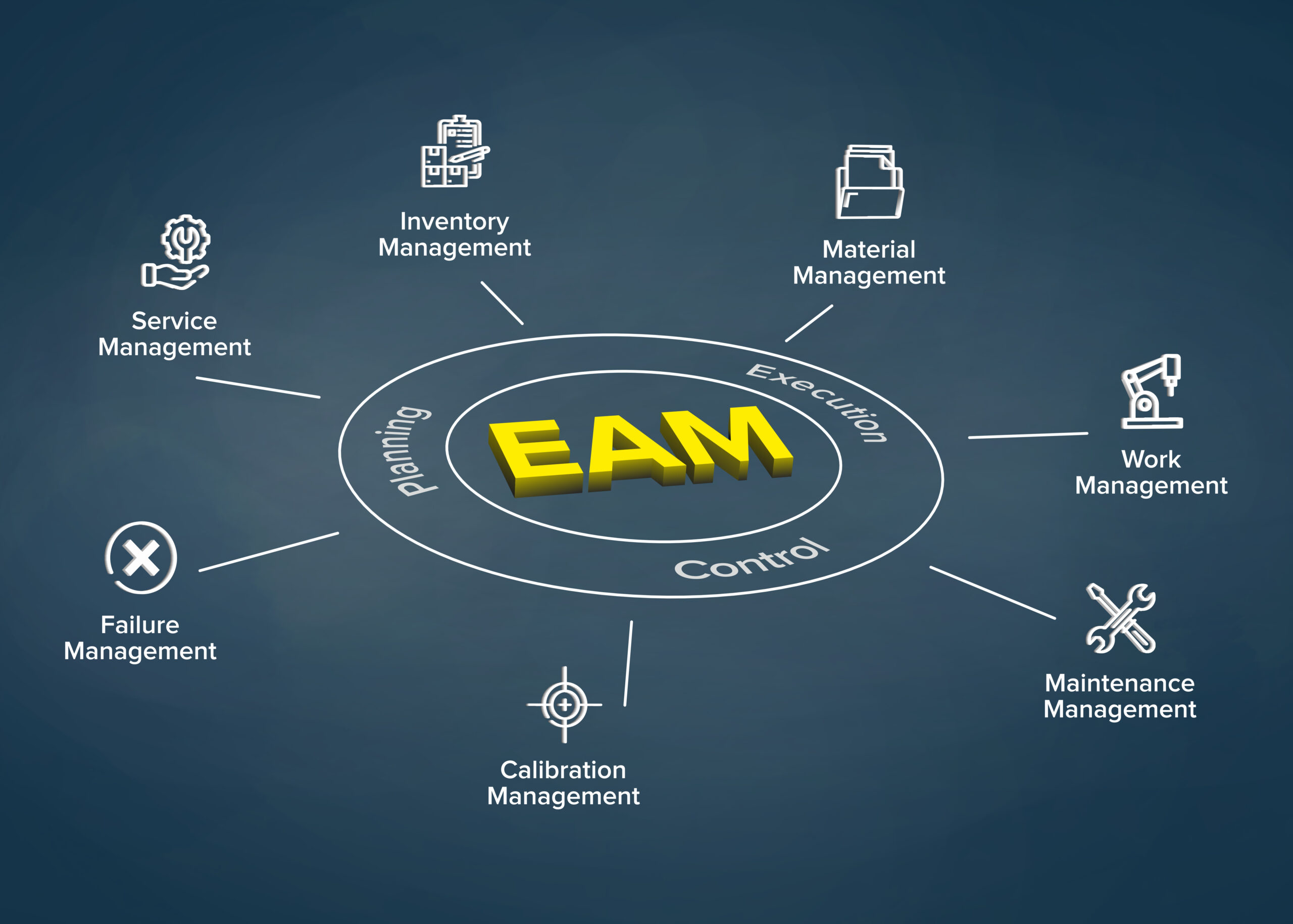

EAM software centralizes all processes related to managing physical assets across their full lifecycle—from acquisition and operation to maintenance and disposal. Unlike basic maintenance tools, EAM platforms integrate:

- Work order management

- Asset health monitoring

- Inventory and spare parts management

- Preventive and predictive maintenance

- Mobile field service tools

- Budgeting and cost tracking

- Reporting and analytics

By digitizing asset workflows, EAM systems deliver visibility into performance, asset health, and total cost of ownership (TCO), enabling data-driven decisions instead of reactive interventions.

Key Cost Drivers in Asset-Intensive Environments

Before examining cost reduction benefits, it helps to understand where maintenance budgets typically go. Common cost drivers include:

- Unplanned downtime

- Emergency repairs

- Shortened asset life

- Over maintenance or under maintenance

- Labor inefficiencies

- Poor spare parts planning

- Inefficient contractor/vendor use

- Regulatory non-compliance penalties

EAM software directly addresses these pain points.

1. Reducing Unplanned Downtime

Unexpected equipment failures are extremely expensive due to:

- Lost production capacity

- Delays and bottlenecks

- Idle labor

- Emergency repair premiums

- Customer service impact

EAM reduces downtime through:

✔ Preventive maintenance scheduling

✔ Predictive insights from condition data

✔ Automated maintenance workflows

✔ Faster fault reporting and response

Platforms like FacilityBot streamline issue reporting through mobile requests, AI-driven classification, and rapid dispatching—cutting resolution time and minimizing downtime.

2. Improving Preventive and Predictive Maintenance

Reactive maintenance is costly and unpredictable. EAM enables a shift to smarter models:

Preventive Maintenance

Tasks are scheduled based on:

- Usage hours

- Time intervals

- OEM recommendations

This reduces failure events and repair costs.

Predictive Maintenance

Predictive programs use:

- IoT sensors

- Condition monitoring

- Performance data

- AI failure predictions

This minimizes both over-maintenance and catastrophic breakdowns.

Research shows predictive programs can reduce maintenance costs by 10–40% and extend asset life by up to 30%.

3. Extending Asset Lifecycle

Asset replacement is capital-intensive. EAM helps extend lifecycle through:

- Better lubrication and servicing

- Real-time fault detection

- Early issue escalation

- Usage optimization

- Environmental condition monitoring

By extending useful life, organizations reduce depreciation costs and defer replacement investments—boosting asset management ROI.

4. Optimizing Labor and Technician Productivity

Maintenance labor inefficiency is a hidden cost drain. EAM improves productivity through:

✔ Automated work order assignments

✔ Digital checklists and procedures

✔ Mobile access for field technicians

✔ Time tracking and performance reporting

Technicians spend less time on paperwork and more time on actual maintenance work.

FacilityBot supports distributed and mobile environments, enabling maintenance teams to respond faster and operate more efficiently.

5. Reducing Spare Parts and Inventory Costs

Inventory-related waste comes from:

- Overstocking high-value spares

- Expired or obsolete parts

- Emergency procurement premiums

EAM software reduces these costs by:

- Monitoring consumption trends

- Forecasting future usage

- Automating reorders

- Reducing storage and carrying costs

This ensures optimal balance between availability and capital tied up in parts.

6. Enhancing Regulatory Compliance and Safety

Compliance failures can result in:

- Fines

- Shutdowns

- Insurance issues

- Liability risks

EAM platforms support compliance through:

✔ Maintenance documentation

✔ Audit logs

✔ Certification management

✔ Asset inspection checklists

✔ Safety workflows

This reduces financial exposure and operational disruption.

7. Improving Capital Planning and Asset Investment Decisions

EAM software provides visibility into:

- Total cost of ownership

- Asset performance benchmarking

- Replacement vs repair analysis

- Depreciation planning

This supports smarter long-term capital planning and stronger ROI justification for equipment investments.

8. Centralizing Vendor and Contractor Management

Contractor maintenance outsourcing is common but can become costly without oversight.

EAM improves vendor performance through:

- Automated service level tracking

- Work verification

- Cost reporting

- Contract compliance controls

FacilityBot simplifies coordination with external contractors via digital work orders and mobile acknowledgment workflows.

How EAM Software Drives ROI

The ROI of EAM comes from cumulative cost efficiencies over time. Common gains include:

- Lower maintenance labor costs

- Reduced downtime and output loss

- Extended asset life

- Reduced spare part spending

- Higher compliance and safety performance

- Reduced emergency repairs

Most organizations see ROI within 12–36 months depending on asset criticality and maturity level.

Why FacilityBot Supports Strong EAM Cost Savings

FacilityBot strengthens cost savings with features such as:

- Preventive maintenance scheduling

- IoT-enabled monitoring

- Mobile fault reporting and response

- Contractor and SLA management

- Energy usage and asset analytics

- AI work classification

- Cloud-based deployment

The platform is built for enterprises seeking modern asset and facility management efficiencies without overly complex legacy systems.

Conclusion: EAM as a Strategic Cost Optimization Tool

EAM software is no longer just a maintenance tool—it is a financial and operational strategy. By improving maintenance planning, reducing downtime, and extending asset life, organizations achieve measurable EAM cost savings and stronger asset management ROI.

As industries grow more asset-intensive, data-driven and AI-powered platforms like FacilityBot will play a central role in enhancing business performance and reducing operational waste.