The facilities management landscape is undergoing one of its most significant transformations ever—driven by artificial intelligence (AI), automation, and intelligent decision-making tools. As organizations seek higher efficiency and lower operational costs, AI in facilities management has become more than a trend; it is now a strategic priority. Modern Computerized Maintenance Management Systems (CMMS) are evolving into AI-powered command centers that allow teams to predict failures, automate workflows, and optimize assets in real time.

This article explores how AI-driven CMMS and predictive maintenance CMMS technology are shaping the future of facilities management—and why solutions like FacilityBot are helping organizations lead this digital transformation.

The Rise of AI in Facilities Management

Traditionally, facility managers relied on reactive maintenance—fixing problems only once they occurred. This meant downtime, tenant complaints, increased repair costs, and inefficient resource usage. The introduction of preventive maintenance brought improvements, but it still depended heavily on manual scheduling and estimations.

Today, AI is eliminating guesswork altogether.

How AI Is Reshaping Facility Operations

AI-powered facility management tools now enable:

- Automation of maintenance scheduling based on real-time equipment performance

- Smarter decision-making through data analytics and machine learning

- Faster fault detection using sensors, IoT data, and anomaly recognition

- Reduced maintenance costs with condition-based interventions

- Improved sustainability metrics through optimized energy use

AI is no longer a supportive tool—it is becoming the operational backbone of modern FM strategies.

What Is an AI-Driven CMMS?

An AI-driven CMMS is an advanced maintenance management platform that uses artificial intelligence to automate workflows, analyze equipment data, and predict potential failures. Unlike traditional CMMS, which only stores and organizes maintenance tasks, AI-driven systems can:

- Identify asset behavior patterns

- Predict maintenance needs ahead of time

- Recommend optimal repair actions

- Allocate resources automatically

- Improve technician productivity

This evolution shifts CMMS from a digital record-keeping tool to an intelligent operations hub.

Predictive Maintenance: The Next Generation of CMMS

Predictive maintenance CMMS combines IoT sensors, machine learning, and CMMS functionality to forecast equipment failures before they happen. Instead of following fixed schedules, maintenance activities trigger when asset data indicates early signs of malfunction.

Key Components of Predictive Maintenance

- Sensors & IoT devices

Monitor temperature, vibration, pressure, runtime hours, energy usage, and more. - Machine learning algorithms

Analyze patterns to detect abnormalities or risks. - Cloud data processing

Enables real-time analysis and remote monitoring. - Automated CMMS workflows

Create work orders instantly when anomalies appear.

Predictive maintenance reduces downtime by up to 50% and decreases maintenance costs by 30–40%, making it essential for modern facilities.

Benefits of AI-Driven CMMS and Predictive Maintenance

Reduced Equipment Downtime

AI identifies issues early, allowing teams to fix problems before they disrupt operations.

Lower Maintenance Costs

Maintenance becomes targeted and optimized rather than excessive or reactive.

Extended Asset Lifecycles

Equipment is maintained based on actual condition, ensuring optimal performance.

Smarter Workforce Allocation

Technicians receive AI-prioritized tasks, streamlining productivity.

Greater Energy Efficiency

AI detects inefficient asset performance and suggests corrective actions.

Data-Driven Strategy Development

Reports and dashboards uncover long-term performance trends for better decision-making.

How AI Transforms Facility Managers’ Daily Work

AI enhances facility managers’ capabilities by:

- Automating routine tasks

- Providing instant insights into asset health

- Sending alerts for anomalies or risks

- Recommending cost-effective repairs

- Assisting in vendor and contractor management

- Improving documentation accuracy

Facility managers can now focus on strategic planning instead of firefighting operational issues.

FacilityBot: Leading the AI Transformation in FM

FacilityBot, a leading AI-powered facility management and CMMS software, integrates modern automation features to support predictive and proactive operations.

FacilityBot’s AI-Driven Capabilities

- Predictive maintenance alerts that notify users before equipment failure

- Connected IoT and BMS integration for real-time asset monitoring

- Smart ticketing automation for service requests and fault reporting

- AI-powered chat and messaging features for tenant communication

- Comprehensive asset management dashboards for performance tracking

FacilityBot helps facility managers reduce downtime, manage maintenance workflows effectively, and achieve high operational visibility—all essential for future-ready FM practices.

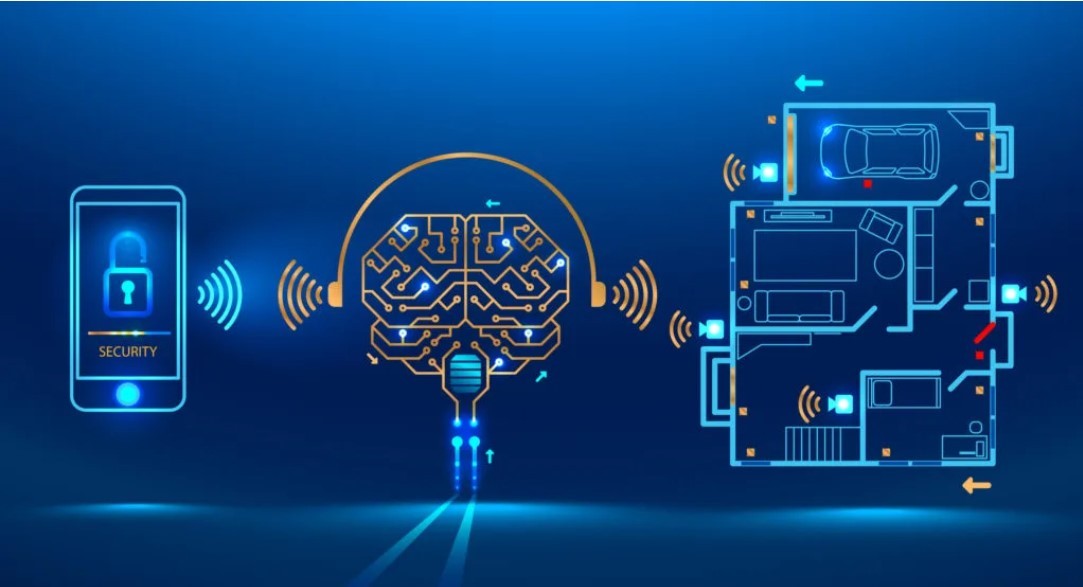

AI + IoT + CMMS = The Future of Facilities Management

The future of facility operations relies on seamless integration between:

- AI for analysis and automation

- IoT sensors for real-time condition data

- CMMS platforms for workflow management

This combination ensures that buildings become smarter, more sustainable, and more efficient every year. Organizations adopting AI-driven facility management today will remain competitive and resilient in a world where data and automation will define operational success.

Conclusion

The future of facilities management is undeniably AI-driven. With advancements in AI in facilities management and the rise of predictive maintenance CMMS, organizations are entering an era of optimized performance, reduced costs, and intelligent decision-making. AI-driven CMMS solutions like FacilityBot are empowering facility teams to transition from reactive and preventive approaches to fully predictive and automated operations.

As we move deeper into 2025 and beyond, the integration of AI, IoT, and CMMS will continue reshaping the industry—turning facilities into smart, self-maintaining environments that deliver unmatched efficiency and value.