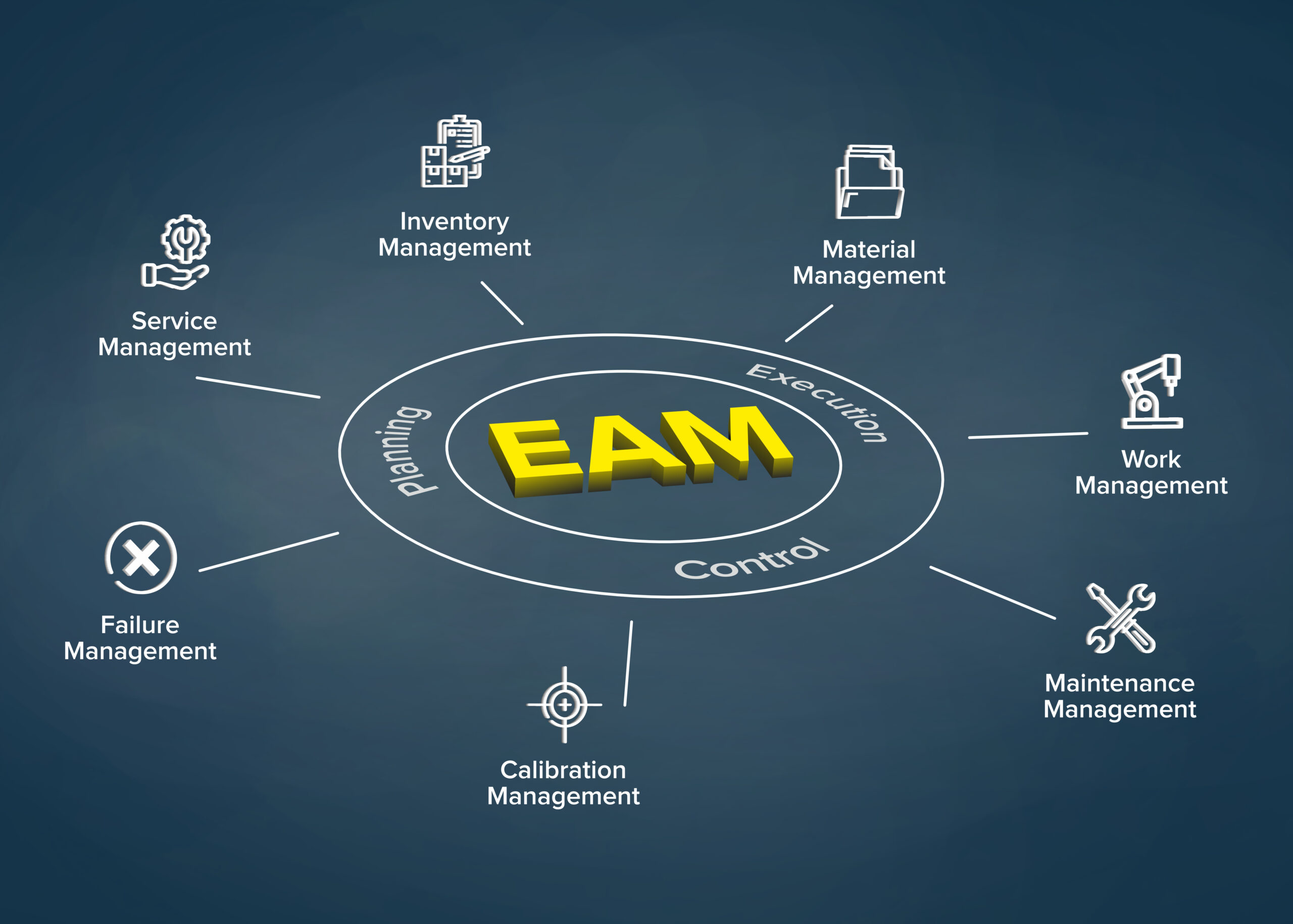

Managing physical assets effectively is one of the biggest challenges for facility managers and asset-intensive organizations. Equipment failures, unplanned downtime, rising maintenance costs, and compliance pressures can all impact operational performance. This is where modern Enterprise Asset Management (EAM) software plays a critical role.

Unlike traditional maintenance tools, modern EAM platforms use data, automation, and AI to manage the entire asset lifecycle—from procurement and installation to operation, optimization, and retirement. Solutions like FacilityBot are helping organizations improve maintenance planning, extend asset lifespans, and make smarter asset decisions.

Understanding the Asset Lifecycle in EAM Software

The asset lifecycle refers to every stage an asset goes through during its usable life. Modern EAM software provides visibility and control across each phase.

Key Asset Lifecycle Stages:

- Planning and acquisition

- Installation and commissioning

- Operation and maintenance

- Optimization and performance analysis

- Decommissioning and replacement

EAM software ensures that asset data, maintenance history, and performance metrics are continuously updated and accessible in one centralized system.

Centralized Asset Data for Better Decisions

One of the biggest advantages of modern EAM software is centralized asset data management. Each asset has a digital profile that includes:

- Asset specifications and documentation

- Maintenance history and work orders

- Warranty and compliance information

- Performance metrics and condition data

This single source of truth enables facility teams to make informed decisions about repairs, upgrades, or replacements.

Platforms like FacilityBot simplify asset tracking while ensuring accurate, real-time information for maintenance teams and managers.

Improved Maintenance Planning with Preventive Strategies

Modern EAM software enables proactive maintenance planning instead of reactive firefighting.

Preventive Maintenance Benefits:

- Reduced unexpected breakdowns

- Improved equipment reliability

- Lower repair costs

- Increased asset availability

EAM systems automatically generate maintenance schedules based on asset usage, time intervals, or manufacturer recommendations. Maintenance teams receive timely work orders, ensuring tasks are completed before failures occur.

Predictive Maintenance with AI and Analytics

Advanced EAM solutions use AI-driven analytics to move beyond preventive maintenance into predictive maintenance.

By analyzing historical data, usage patterns, and sensor inputs, EAM software can:

- Predict potential failures

- Identify abnormal performance trends

- Recommend optimal maintenance timing

This approach helps organizations minimize downtime and avoid unnecessary maintenance activities. FacilityBot supports data-driven maintenance planning by connecting asset data with actionable insights.

Optimizing Maintenance Resources and Costs

Effective maintenance planning is not just about scheduling—it’s also about resource optimization. Modern EAM software improves:

- Labor allocation and workforce planning

- Spare parts inventory management

- Maintenance cost tracking

By understanding which assets require the most attention, facility managers can prioritize high-impact tasks and control maintenance budgets more effectively.

Enhancing Compliance and Risk Management

Compliance with safety regulations, industry standards, and internal policies is critical for many facilities. Modern EAM software simplifies compliance management by:

- Automating inspection schedules

- Tracking certifications and audits

- Generating compliance reports

Having accurate asset records reduces risk and ensures organizations are always audit-ready.

Mobile and User-Friendly Maintenance Execution

Modern EAM platforms are designed for mobile-first maintenance teams. Technicians can:

- Access asset information on-site

- Receive and update work orders in real time

- Upload photos, notes, and inspection results

FacilityBot enhances usability by enabling easy fault reporting and maintenance requests through familiar communication channels, improving response times and team efficiency.

Extending Asset Lifespan and Maximizing ROI

By combining lifecycle visibility, preventive maintenance, and predictive insights, modern EAM software significantly extends asset lifespans. This results in:

- Better return on asset investments

- Reduced capital replacement costs

- Improved long-term planning

Organizations can delay costly replacements and ensure assets perform optimally throughout their lifecycle.

Why FacilityBot Supports Smarter Asset Lifecycle Management

FacilityBot is a modern facility management platform that complements EAM strategies by simplifying maintenance planning, asset tracking, and service workflows.

Key Advantages of FacilityBot:

- Centralized asset and maintenance management

- Automated work order workflows

- AI-powered fault reporting and insights

- Seamless communication between teams

FacilityBot helps organizations bridge the gap between traditional EAM systems and modern, AI-driven facility operations.

Final Thoughts

Modern EAM software is essential for organizations looking to improve asset lifecycle management and maintenance planning. By leveraging centralized data, preventive and predictive maintenance, and AI-driven insights, facilities can reduce downtime, control costs, and maximize asset performance.

Platforms like FacilityBot enable facility teams to modernize their maintenance operations while maintaining flexibility and ease of use. Investing in the right EAM solution today ensures more resilient, efficient, and future-ready facilities tomorrow.