Efficient maintenance is not just about fixing things when they break — it’s about identifying faults early, tracking issues systematically, and resolving them before they escalate. This is where a well-structured fault reporting process becomes essential. In today’s fast-paced operational environments, the ability to capture, report, and respond to faults in a timely manner can significantly impact uptime, asset performance, and workplace safety.

In this guide, we’ll explain the fault reporting process, its benefits, and how to implement it effectively. Whether you’re managing equipment in manufacturing, overseeing a building’s maintenance, or ensuring compliance in critical infrastructure, understanding this process is key to long-term success.

What is the Fault Reporting Process?

The fault reporting process is a structured method used by organizations to detect, document, report, and resolve equipment or system failures. This process ensures that issues are identified early, communicated to the right personnel, and resolved efficiently, often using CMMS software or facilities management software.

Here’s a step-by-step overview of how the fault reporting process typically works:

Step 1: Fault Identification

The process begins when a fault is identified. This could come from frontline employees, technicians, automated monitoring systems, or routine inspections. Recognizing unusual sounds, reduced performance, leaks, or visible damage are all examples of how faults might be detected.

Step 2: Reporting the Fault

Once identified, the fault must be reported using an established channel:

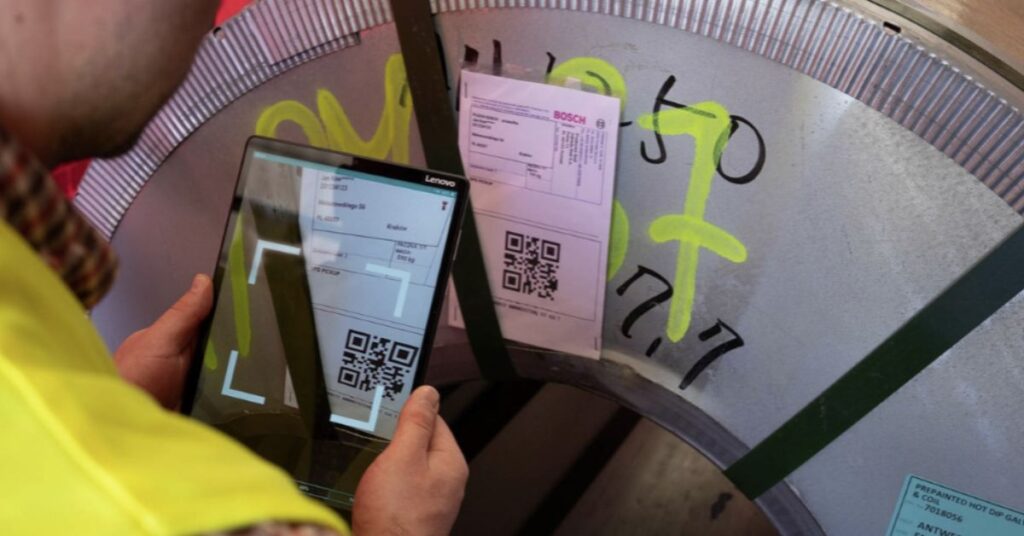

- Digital Platforms/CMMS Software: Many organizations now use Computerized Maintenance Management Systems (CMMS) that allow users to submit faults via desktop or mobile apps.

- Hotlines/Helpdesks: A traditional option where faults are reported via phone or messaging service.

- Physical Logbooks: Used in less digitized environments, faults are manually recorded in a shared book.

These systems collect vital details such as location, asset ID, fault description, and urgency level.

Step 3: Information Collection

Effective reporting requires context. Most digital systems allow for supporting data like:

- Date and time of fault discovery

- Asset or system involved

- Photos or videos

- Symptoms or observations

This helps maintenance teams quickly understand the issue.

Step 4: Notification & Acknowledgement

Once a fault is reported, an automated notification is sent to the maintenance team or relevant personnel. The individual who submitted the fault typically receives a confirmation message, acknowledging receipt and providing a ticket number or tracking ID.

Step 5: Categorization & Prioritization

Reported faults are sorted based on their severity and impact. High-priority issues affecting safety or production are escalated immediately, while minor issues are queued accordingly. This prioritization helps allocate resources efficiently and reduces downtime.

Step 6: Assignment & Scheduling

The fault is then assigned to a technician or team, often through integrated CMMS software. A work order is generated, and resolution tasks are scheduled. These platforms often allow managers to track open tickets and verify that issues are addressed within SLAs.

Step 7: Fault Resolution

Technicians resolve the issue based on the fault details provided. The resolution process is documented, including:

- Tasks performed

- Replacement parts used

- Labor hours involved

- Any recurring patterns noticed

Step 8: Feedback & Communication

After resolution, the individual who reported the fault is updated. This feedback loop not only builds trust but also encourages continued participation in the fault reporting process.

Step 9: Analysis & Continuous Improvement

Fault data is analyzed to identify trends such as recurring equipment failures or delayed responses. This allows organizations to adjust maintenance strategies, implement preventive measures, and improve their asset reliability over time.

Why is Fault Reporting Important?

Implementing a robust fault reporting process brings several critical benefits:

- Early Detection: Spot issues before they cause severe disruptions.

- Asset Longevity: Timely intervention prevents damage and extends equipment life.

- Workplace Safety: Helps organizations remain compliant with safety regulations.

- Operational Efficiency: Minimizes unplanned downtime and improves productivity.

- Data-Driven Decisions: Allows for trend analysis and better maintenance planning.

Best Practices for Effective Fault Reporting

To optimize the fault reporting process:

- Establish clear procedures that employees can easily follow

- Train staff and build a culture of accountability

- Use digital tools like CMMS or facilities management software for tracking

- Provide feedback to those who report faults

- Regularly audit the system to find and fix process gaps

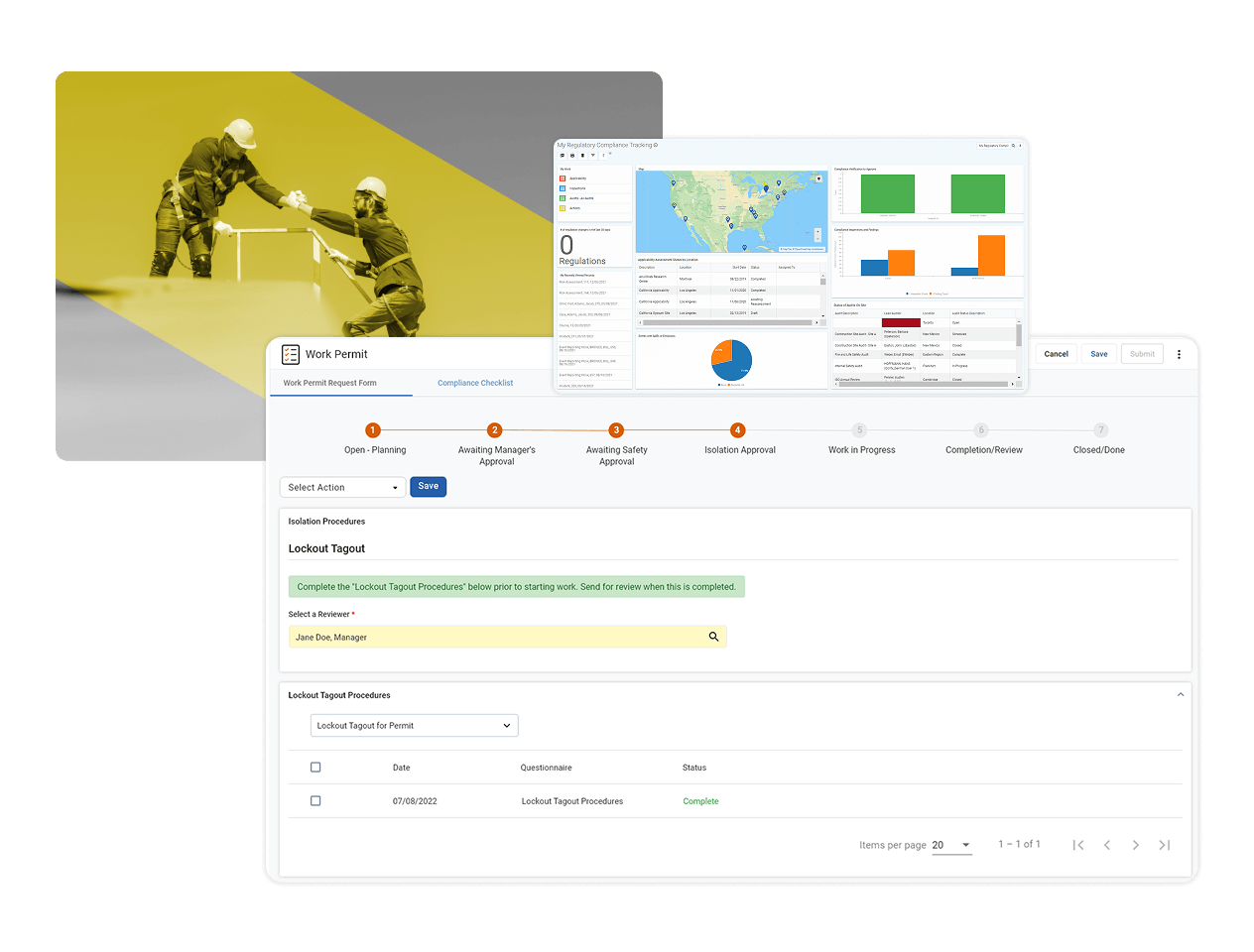

How FacilityBot Enhances Fault Reporting

When it comes to streamlining your maintenance operations, FacilityBot offers an all-in-one solution. As a cloud-based facilities management software and CMMS software, FacilityBot enables teams to report faults via messaging platforms, mobile apps, or desktop portals — with automated workflows to assign, track, and resolve issues efficiently.

Its intuitive dashboard, asset tagging, and analytics empower facility managers to reduce downtime, boost productivity, and ensure safety compliance — all while offering seamless integration with existing maintenance workflows.

If you’re looking to improve your fault reporting process and enhance operational visibility, FacilityBot is the smart, scalable choice for modern facilities management.