Introduction: Preventing equipment failures is a cornerstone of efficient facility management, ensuring smooth operations and significant cost savings. In this comprehensive article, we delve into the transformative power of predictive maintenance with CMMS (Computerized Maintenance Management System) in proactively averting equipment failures. By exploring real-time equipment monitoring, early issue detection through data analytics, and conditional maintenance triggers, we aim to showcase the unparalleled effectiveness of predictive maintenance. Drawing from compelling use case studies and industry examples, we will demonstrate how this approach enhances equipment reliability, minimizes downtime, and maximizes operational efficiency. We will emphasize the indispensable role of CMMS in facilitating proactive maintenance scheduling and optimizing equipment performance. Engaging and insightful, this article will provide facility managers with valuable insights into harnessing the power of predictive maintenance to elevate facility reliability.

1. Real-Time Equipment Monitoring: Unveiling Hidden Insights

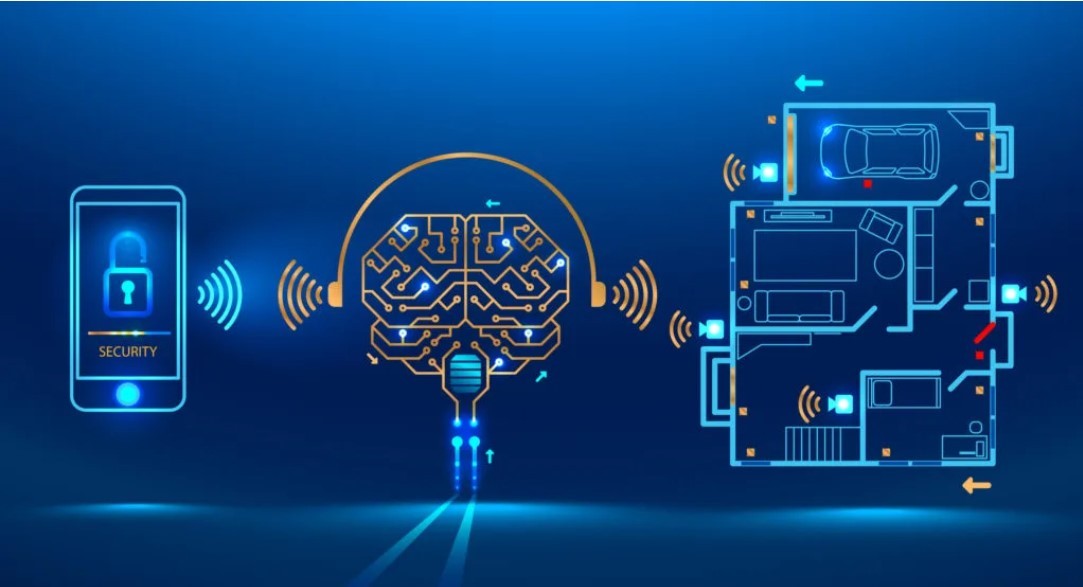

The conventional reactive maintenance approach often leads to equipment failures and costly downtime. With the integration of CMMS and IoT technologies, facility managers gain the ability to monitor equipment health in real time. Sensors and IoT devices attached to critical assets collect and transmit real-time data, providing immediate insights into asset performance. Facility managers can track critical parameters, such as temperature, pressure, vibration, and energy consumption, and receive instant alerts for deviations. This real-time monitoring allows them to proactively address emerging issues before they escalate into costly failures. By exploring real-life examples, we will highlight the significant impact of real-time equipment monitoring on preventing unexpected downtime and extending equipment lifespan.

For instance, a manufacturing plant implemented CMMS with IoT sensors on their production line machinery. The real-time data allowed the facility manager to detect a gradual increase in vibration levels on one machine. Timely intervention revealed a loose component, preventing an impending breakdown and saving the company from significant production losses.

2. Early Issue Detection with Data Analytics: Leveraging the Power of Data

Data-driven decision-making is at the core of predictive maintenance. CMMS leverages advanced data analytics to identify patterns and trends that indicate potential equipment issues. Facility managers can analyze historical maintenance data, failure patterns, and equipment performance trends to predict possible faults. By proactively addressing these issues, facility managers can optimize maintenance resources, minimize costs, and enhance equipment reliability.

Through data analysis, CMMS can recognize subtle changes in equipment performance that might go unnoticed by manual inspections. By using this data-driven approach, facility managers can plan maintenance activities more efficiently and avoid unnecessary repairs or replacements.

3. Conditional Maintenance Triggers: Timing Maintenance Right

Conditional maintenance, triggered by real-time equipment data and performance thresholds, enables proactive and efficient maintenance practices. With CMMS, facility managers can set condition-based triggers that automate maintenance tasks when specific thresholds are met. For instance, a CMMS can automatically schedule maintenance when an asset’s performance deviates from its optimal range or when a certain number of runtime hours are reached.

This approach ensures that maintenance interventions occur at the optimal time, maximizing equipment performance and minimizing operational disruptions. By addressing potential issues before they lead to failures, facility managers can avoid costly breakdowns and extend the lifespan of critical assets.

4. Use Case Studies: Realizing the Power of Predictive Maintenance

Use case studies will be integrated throughout the article to illustrate the tangible benefits of predictive maintenance. We will present examples from various industries where predictive maintenance, facilitated by CMMS, has resulted in reduced downtime, increased equipment reliability, and substantial cost savings. These case studies will serve as compelling evidence of the transformative impact of predictive maintenance on facility operations.

For instance, a commercial property management company adopted CMMS to monitor the HVAC systems in its buildings. By analyzing data trends, the facility manager identified a pattern of increased energy consumption during specific hours. Armed with this insight, the facility manager optimized the system’s schedule, resulting in reduced energy costs and increased overall energy efficiency.

Conclusion: Fostering Unprecedented Facility Reliability

As we conclude this in-depth exploration, it becomes evident that predictive maintenance with CMMS is a game-changer in facility management. The real-time equipment monitoring, data-driven insights, and conditional maintenance triggers enable facility managers to proactively prevent equipment failures, ensuring smooth operations and cost-effective maintenance practices. By embracing FacilityBot and its cutting-edge CMMS software, facility managers can leverage predictive maintenance tools to foster unprecedented facility reliability, setting a new standard for operational excellence.

As technology continues to evolve, adopting a predictive maintenance approach will be key to staying ahead in the competitive landscape of facility management. By incorporating CMMS and predictive maintenance into their operations, facility managers can elevate equipment performance, reduce maintenance costs, and optimize overall facility efficiency. Embracing this proactive approach to maintenance will not only prevent costly equipment failures but also drive long-term success for facilities in various industries. With the power of CMMS and predictive maintenance at their disposal, facility managers can confidently navigate the complexities of equipment reliability and achieve unparalleled facility performance.