Introduction:

Picture this: a manufacturing plant buzzing with activity, where every second counts and efficient maintenance is the backbone of productivity. In the past, managing maintenance tasks was a labyrinthine challenge, with paperwork piling up, assets falling into disrepair, and valuable time wasted. But then, a remarkable solution emerged – the Computerized Maintenance Management System (CMMS). This is the tale of how CMMS became the knight in shining armor for maintenance management, propelling organizations towards unparalleled success. In this captivating article, we will embark on a journey to explore the transformative power of CMMS, unearthing its hidden gems that go beyond the conventional benefits, and discover how it can breathe new life into maintenance operations.

- Streamlined Maintenance Scheduling:

The first chapter in our CMMS saga unveils its ability to streamline maintenance scheduling. Like a conductor orchestrating a symphony, CMMS optimizes the allocation of resources, reducing downtime and enhancing productivity. With CMMS, maintenance teams can plan and prioritize tasks, assign them to technicians, and monitor their progress, ensuring efficient operations that keep the wheels turning smoothly.

- Real-time Asset Intelligence:

Our adventure continues with the revelation of CMMS as a treasure trove of real-time asset intelligence. Think of it as a crystal ball, providing organizations with a comprehensive view of their assets’ health, performance metrics, and crucial insights. Armed with this knowledge, decision-makers can make informed choices regarding maintenance strategies, equipment replacement, and resource allocation, safeguarding against unexpected breakdowns and unleashing the full potential of their assets.

- Enhanced Work Orders and Requests:

Every great story has a hero, and in the realm of CMMS, work orders and service requests take center stage. With CMMS as the supporting protagonist, organizations witness a revolution in workflow management. The system serves as a digital command center, ensuring seamless communication, improved collaboration, and timely task completion. Work orders and service requests become a well-choreographed dance, harmonizing the efforts of technicians and stakeholders to deliver exceptional results.

- Promoting Safety and Cultivating Health:

As our tale unfolds, we uncover CMMS’s unwavering commitment to safety and the well-being of maintenance teams. Within its digital realm, CMMS embeds safety protocols, checklists, and compliance measures, nurturing a culture of security and mitigating risks. Technicians access vital safety procedures, equipment checklists, and material safety data sheets, empowering them to perform their duties with utmost care. By prioritizing safety, organizations not only protect their employees but also reduce accidents, liabilities, and downtime, paving the way for a safer and more productive environment.

- Efficient Purchase Order Mastery:

In our epic journey, we encounter CMMS’s prowess in mastering purchase order management. Like a skilled merchant, CMMS enables organizations to track and monitor purchase orders seamlessly. This ensures timely procurement of maintenance materials, minimizing delays, preventing stockouts, and maintaining a well-oiled supply chain. With accurate inventory records at their fingertips, organizations can optimize their procurement processes, eliminate unnecessary costs, and achieve unparalleled efficiency in their maintenance operations.

- Collaborative Flexibility:

As our tale nears its climax, we discover CMMS’s ability to foster collaboration through flexible user permissions. Like a conductor leading an orchestra, CMMS enables organizations to harmonize internal and external stakeholders. By granting guest user permissions, organizations can collaborate with vendors, contractors, and auditors seamlessly. This fluidity in collaboration promotes transparency, strengthens partnerships, and propels maintenance operations to new heights of success.

- Fortifying Compliance through Audit Systems:

In the final chapter of our CMMS chronicle, we encounter its power to fortify compliance through robust audit systems. With CMMS as the guardian of regulatory standards, organizations can effortlessly track and document maintenance activities, inspections, and certifications. These audit systems not only ensure adherence to industry regulations but also provide valuable data for

performance analysis, continuous improvement, and future planning.

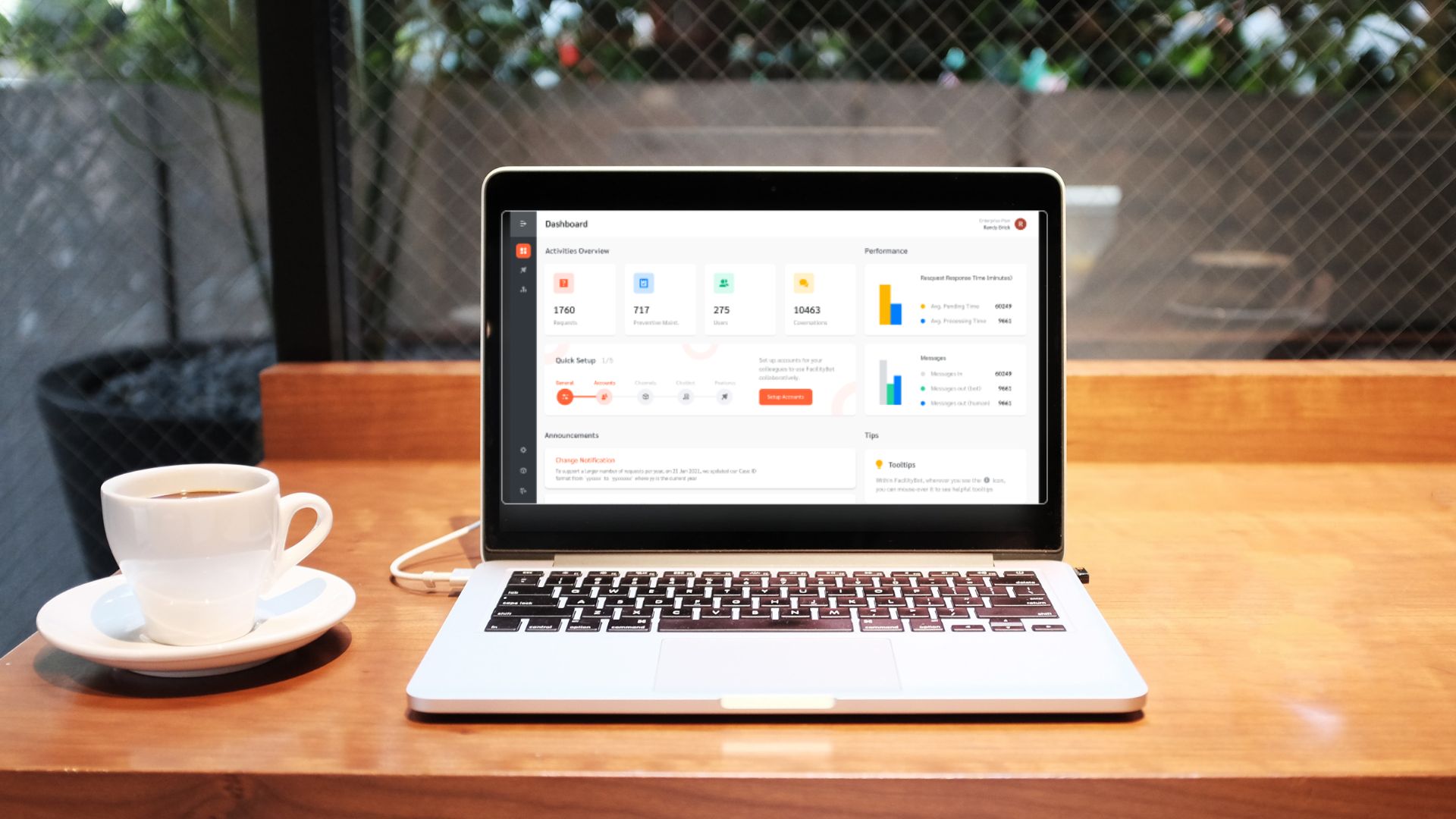

FacilityBot CMMS: Unleash the Full Potential of Maintenance Excellence

As our story concludes, it is imperative to introduce FacilityBot CMMS as the true catalyst for maintenance excellence. With its exceptional capabilities, user-friendly interface, and unwavering reliability, FacilityBot CMMS reigns supreme in the realm of maintenance management. Seamlessly integrating all the transformative elements we’ve explored, FacilityBot CMMS empowers organizations to embark on a new era of maintenance efficiency, safety, and success.

Embark on your own journey towards maintenance excellence with FacilityBot CMMS. Visit our website at https://facilitybot.co and unlock the full potential of your maintenance operations. Experience a unique and captivating CMMS adventure that will reshape the way you perceive maintenance management.

In conclusion, CMMS is not just a mundane tool but an enchanted key that unlocks a world of benefits for organizations. By streamlining maintenance scheduling, providing real-time asset intelligence, enhancing work orders and requests, prioritizing safety, optimizing purchase order management, fostering collaboration, and fortifying compliance, CMMS becomes a beacon of maintenance excellence. Join us in this extraordinary expedition, and let CMMS be your guide to a realm of unparalleled success in the realm of maintenance management.